Why Ozone?

Ozone is faster, safer, and more environmentally friendly than traditional chemicals. Ozone’s ability to kill anaerobic organisms is 3,000 times more powerful than chlorine, but presents no danger to workers when used in AWOCSTM. The EPA and FDA have investigated the AWOCSTM and have ensured its process to be acceptable.

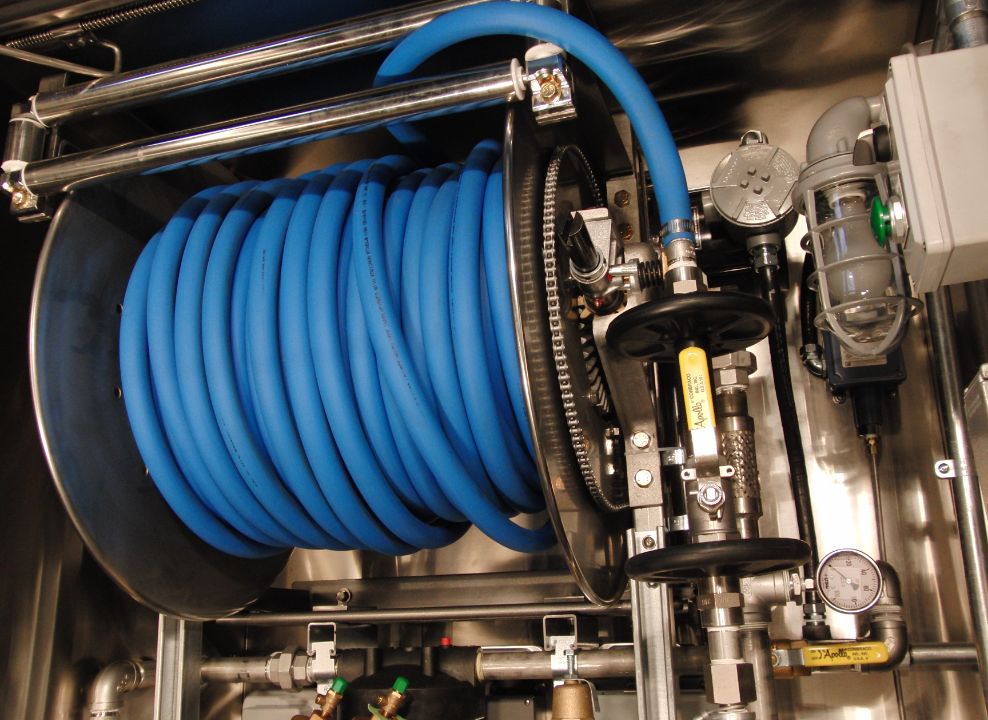

AWOCS™ UNITED STATES PATENT NO. US 7,311,817 B2 AND 7,351,329