Dampener Pressurized Feed Assembly and Water Purification System

Situation

The newspaper business was still going strong in the early and mid-1980s. Cellular telephones were just starting to appear and personal computers in the workplace were popping up around industry. Still, it would be another 10 to 15 years before the internet would have any impact on newspaper circulation. During this period a number of newspapers were converting from all black and white to include color on front pages and the “funnies”. Advertisements and such were color as well. This meant a change in the demands of the printing press. The new off-set ink printing presses required dampener supply systems that were supplied with RO permeate water to ensure a consistent base for the chemical solution. The dampener solution or etching solution is the product that is sprayed on the rollers of the press to repel the ink for non-image areas of the newspapers.

Case Evaluation – A large printing press OEM company

A large OEM firm engaged Semler Industries in order to improve and expand their offering of newspaper printing press ancillary equipment. Special attention to each complete system was necessary, because the dampener solution flow rate requirement is critical to proper imaging on each page, and tightly correlated with the number of spray bars on each press. Once calculations were completed, the correct components were selected to meet the unique requirements of each system.

In addition to correct pump selection, the application requirements included:

- 100% suspended solids removal

- 100% algae removal

- 99.5% bacterial removal

- 90 – 95% of dissolved salts removed

Since Semler’s systems performed a conversion of existing equipment, it was not a cost reduction, but rather an improvement project. The payoff was returned through increased market penetration and additional market share, as well as lower warranty claims and maintenance requirements as a result of more robust equipment.

In 1987 Springfield Army Times Journal was the first facility to purchase a printing press system with Semler’s ancillary equipment included. A much larger application was installed in 1988 at the News and Sun Sentinel in Ft. Lauderdale, FL. Since then, dozens of systems have been provided to newspapers throughout the world.

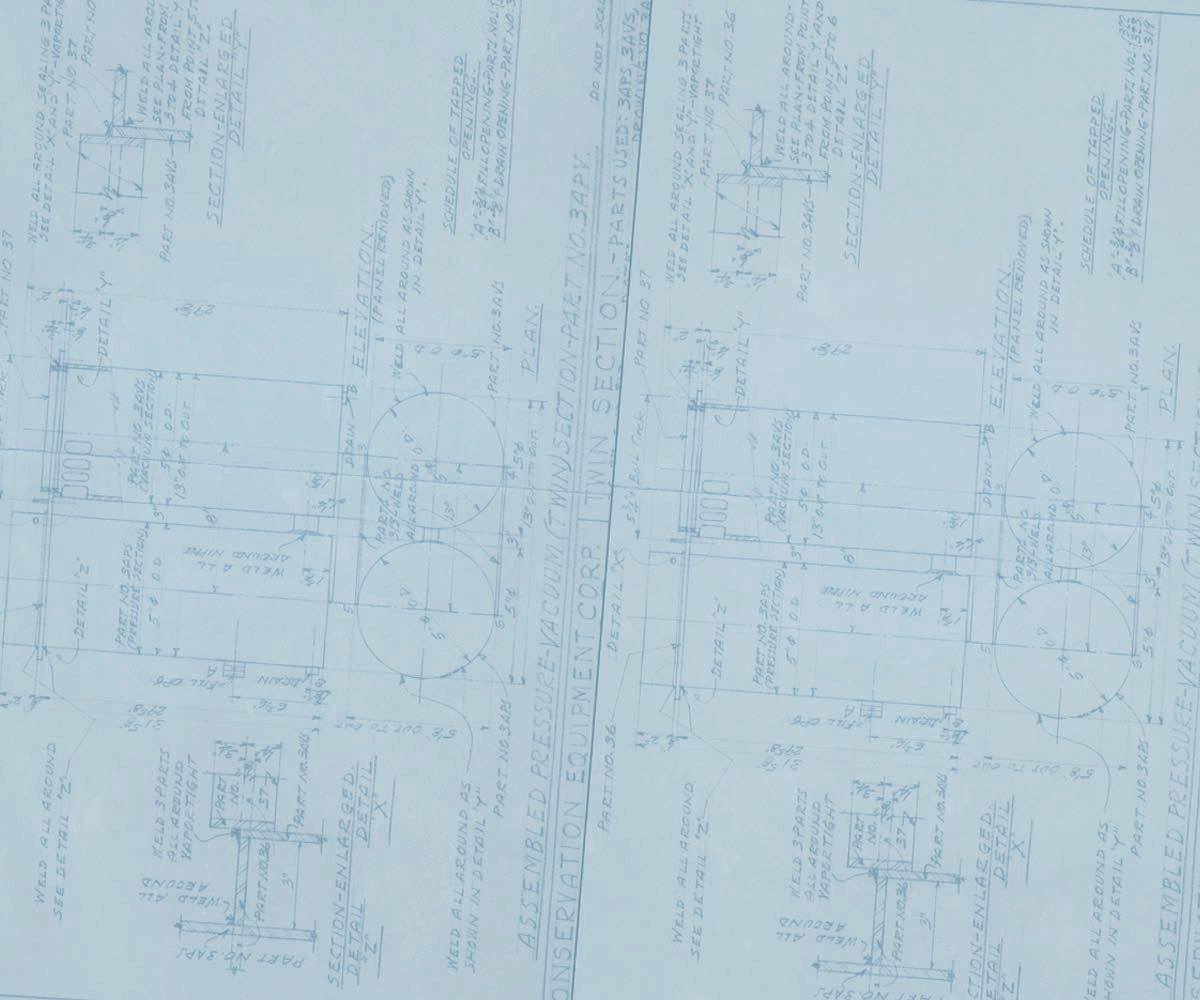

Equipment Description

The equipment was designed to function with 480V power, in order to match the facilities’ available power source. The “heart” of the system, known as the Pressurized Feed Assembly, or PFA, was originally planned as a skid, but it became apparent that a cabinet design carried significant advantages. When the cabinet was locked, it would prevent tampering which could lead to unnecessary down time . Additionally the cabinet provided protection from the environment, which meant less dust and greater reliability.

Also included in the equipment package was a water pretreatment system, water purification system, , concentrate pressurizing system and transfer pump assembly.

Due to the critical nature of the equipment (if a printing press at a newspaper became non-functional, the morning addition could not be delivered), reliability and redundancy were built into every system. How reliable? There was a three-year guarantee included with the system. In order to offer additional assurance to the end-users, and to service older equipment, Semler also maintained inventory for all critical parts, available for over-night delivery to almost anywhere in the world.

This equipment has been installed in 40+ newspapers around the United States and South America. Locations such as New York Times, Los Angeles Times, Denver Post, Philadelphia Inquirer in the US and other papers in Rio De Janeiro, Brazil; Puerto Rico News; Toronto, ON; Lima, Peru; and Victoria, BC all boast a Semler Press Dampener supply and RO Water systems.

Regardless of water source being city, well, or river (as used at some South American installations), the correct design and combination of equipment was selected to insure trouble-free start-up and on-going performance. Even the water purification membranes came with a 3-year guarantee, which further supported confidence in the reliability of the equipment.

Recommendations

As many of the US facilities are reducing costs or closing altogether, this market is not growing domestically. However, internationally, as electronics will still take a few years to catch up, Semler Industries continues to support and grow this market to those with need.

References

- William Schulz’s personal files.

- Semler Dampener Pressurized Feed Assembly.

Related Imagery

[nggallery id=1]