Continue below to learn more about the 3 main types of Potable Water Cabinets within our offering.

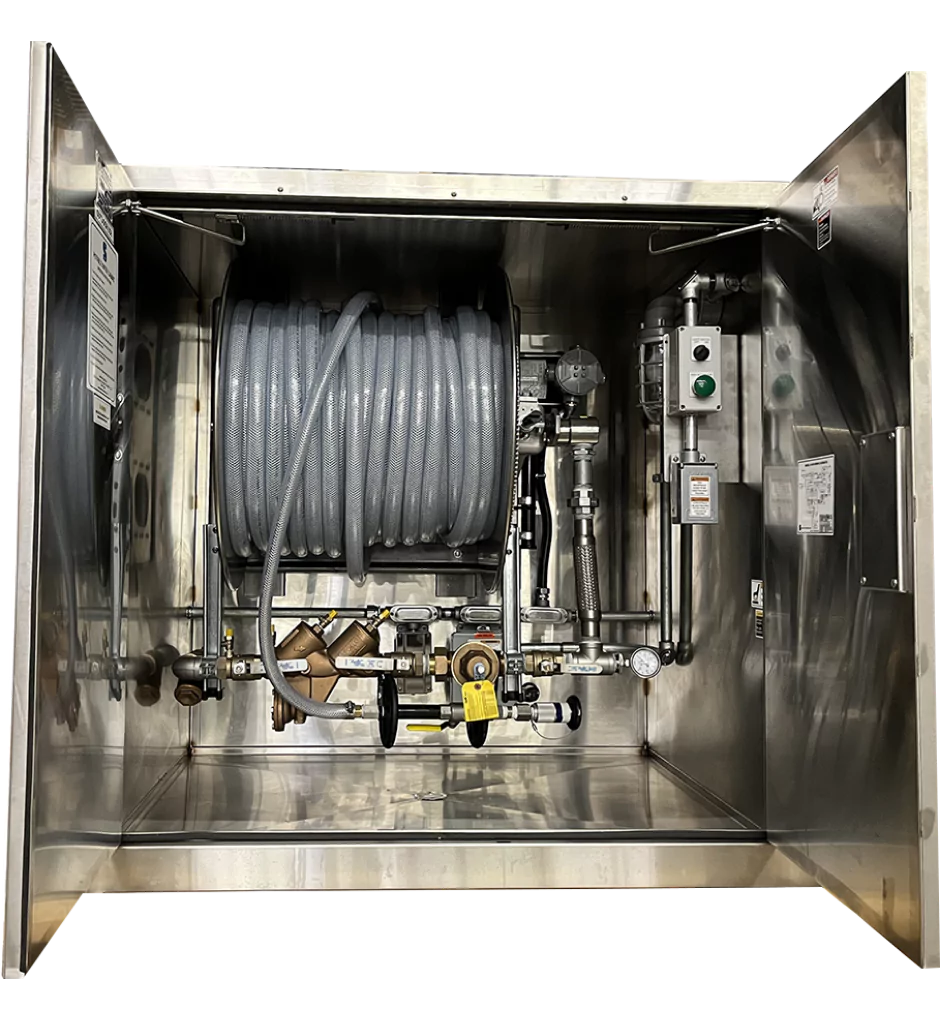

Standard Potable Water Cabinet

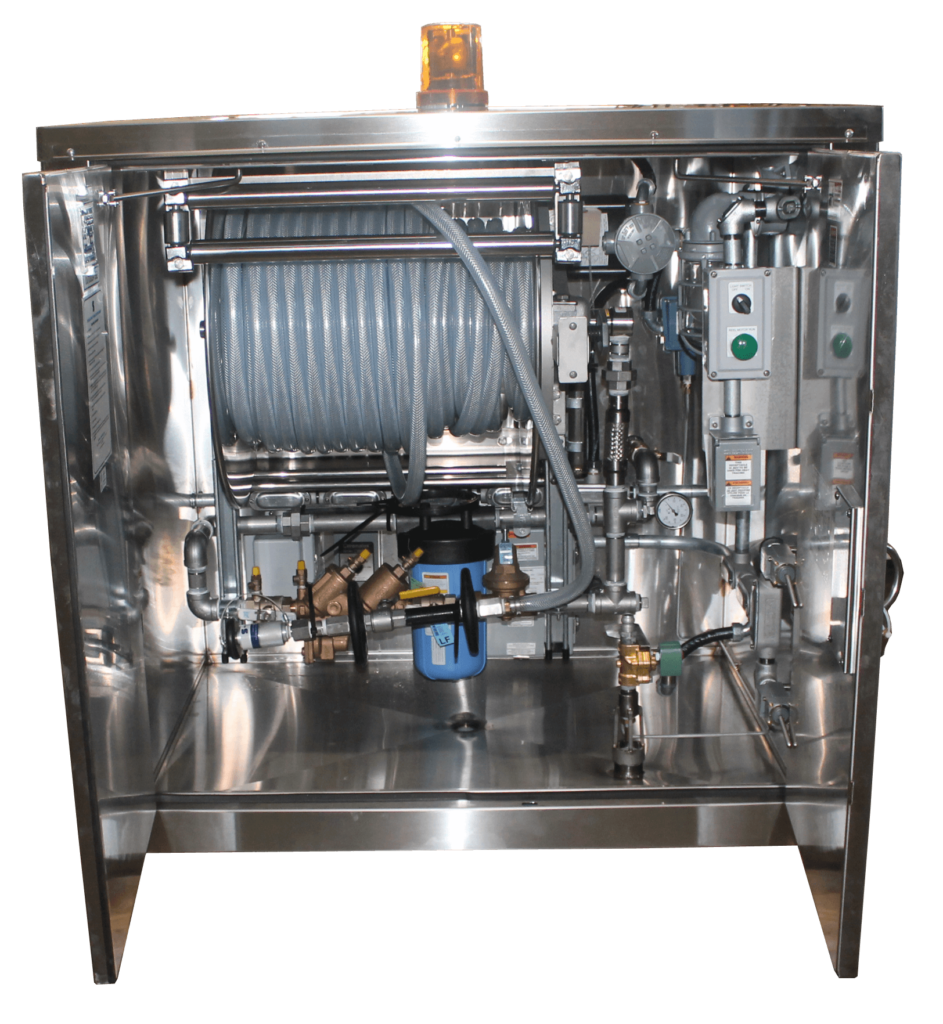

Semler’s Standard PWC has a dependable, stainless-steel construction and high-polish finish to guarantee longevity, while the easy-to-clean design helps improve sanitary conditions. These are offered in 4 models to meet the demands of all climates.

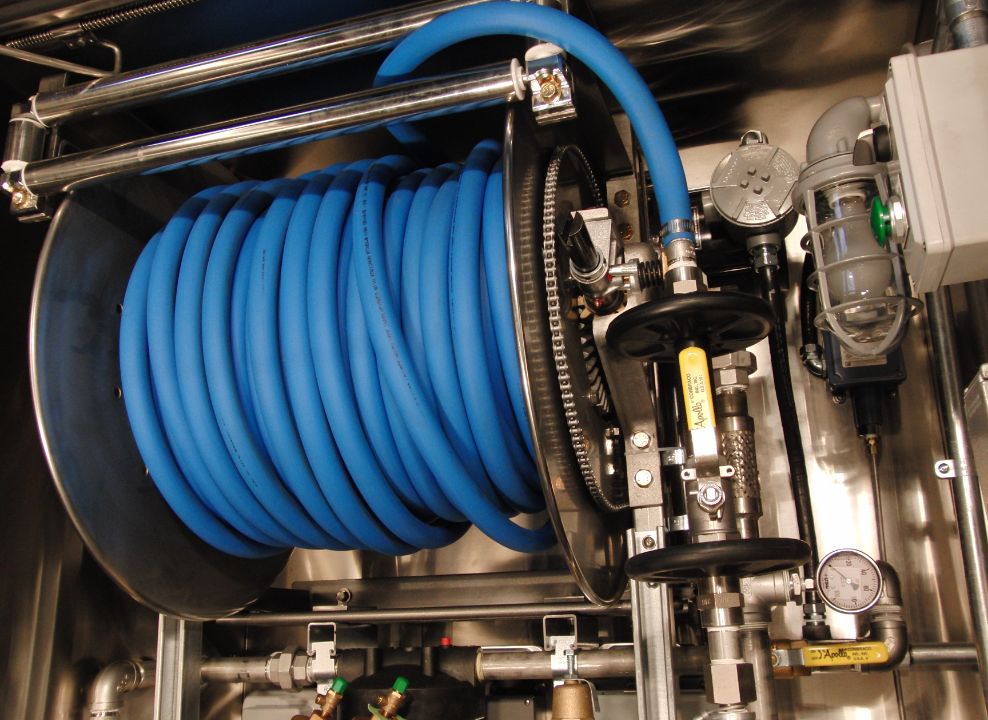

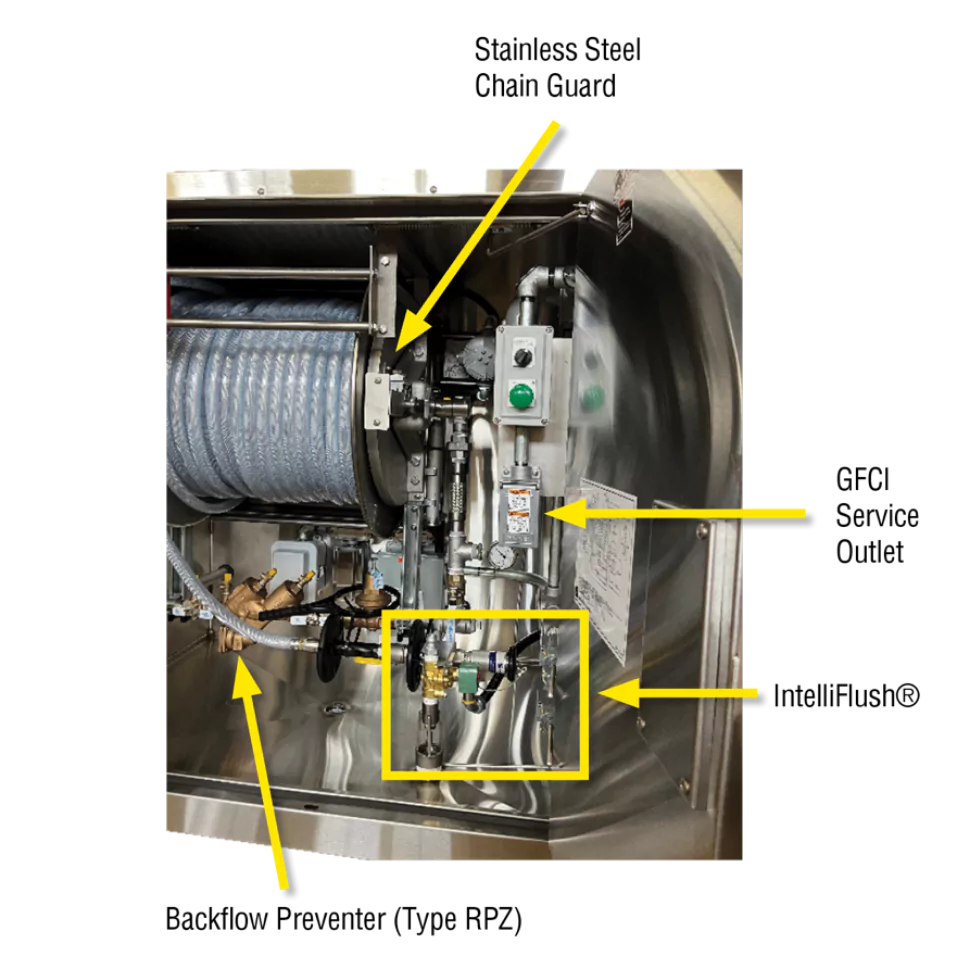

IntelliFlush®

The Smart Potable Water Cabinet

Designed to ensure consistent water quality, the Semler Industries’ patented IntelliFlush® is the most technologically advanced PWC on the market. Based on idle time, gate activity, and weather conditions, the IntelliFlush® can detect when conditions for bacterial growth exist. When appropriate, the system automatically flushes water from the plumbing and replenishes it with fresh, clean water. IntelliFlush® features are available with both Standard and High Flow PWC models.

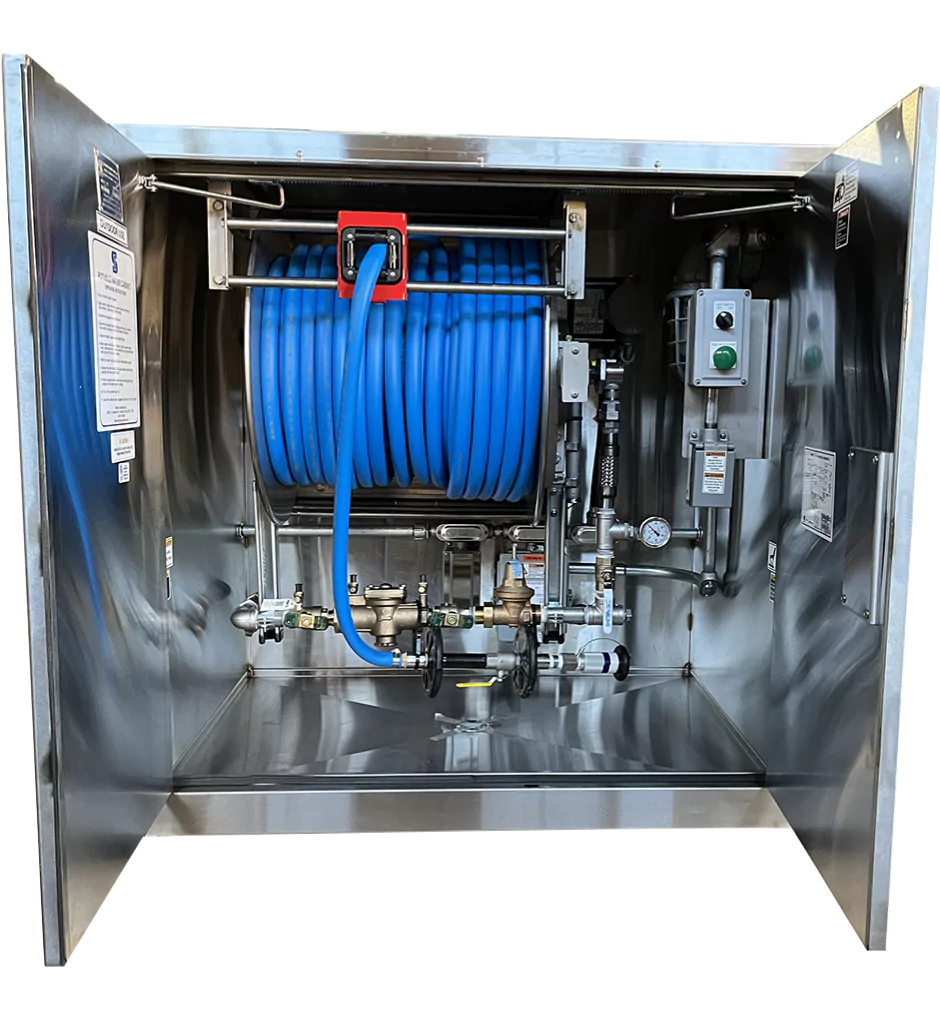

High Flow Potable Water Cabinet

The High Flow PWC is designed to allow flow rates of up to 25 gallons per minute to service larger aircraft with high capacity potable water tanks efficiently. This unit is engineered with the same features as our Standard PWC but in a slightly bigger cabinet in order to accommodate its larger hose reel and hose.