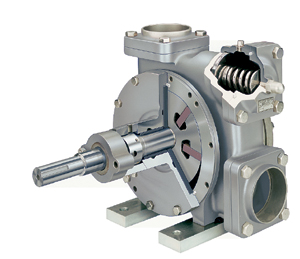

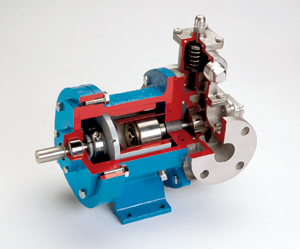

Blackmer’s Sliding Vane Pumps are durable, easy to maintain products well-suited to the Chemical Industry. The unique sliding vane design maintains efficiency as the vanes wear. This means less maintenance and lower energy costs. In addition, every Blackmer sliding vane pump features dual shaft support bearings for smooth operation and even loading. Also, the nature of the Blackmer Sliding Vane pump allow for excellent dry-run and self-priming capabilities. Should the pump require maintenance, the vanes can be replaced without removing the pump from the piping system.

In addition to Blackmer’s Full Line of Sliding Vane Pumps, the following models are specialized options for the Chemical Industry:

Please click the links below for a product brochure

- Seal-less magnetic coupling makes this pump ideal for highly caustic solvents and VOC’s

- 316 Stainless Steel Construction

- Unique bearing and head design allow for fluid to enter the containment can for cooling purposes

- Samarium-cobalt magnets prevent magnet degradation

- Replaceable end discs allow for rebuilding of the pump without removing it from the piping system

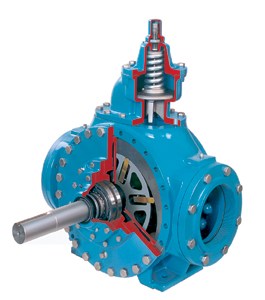

- Designed for applications that have varying fluid viscosities and temperatures

- Available with John Crane or Flowserve mechanical seals as well as other aftermarket seal manufacturers

- Jacketed option allows for high temperature operation

- Available in Stainless Steel Configurations

- Replaceable liners and end discs allow for rebuilding of the pump without removing it from the piping system

- Excellent self-priming and dry-run capabilities

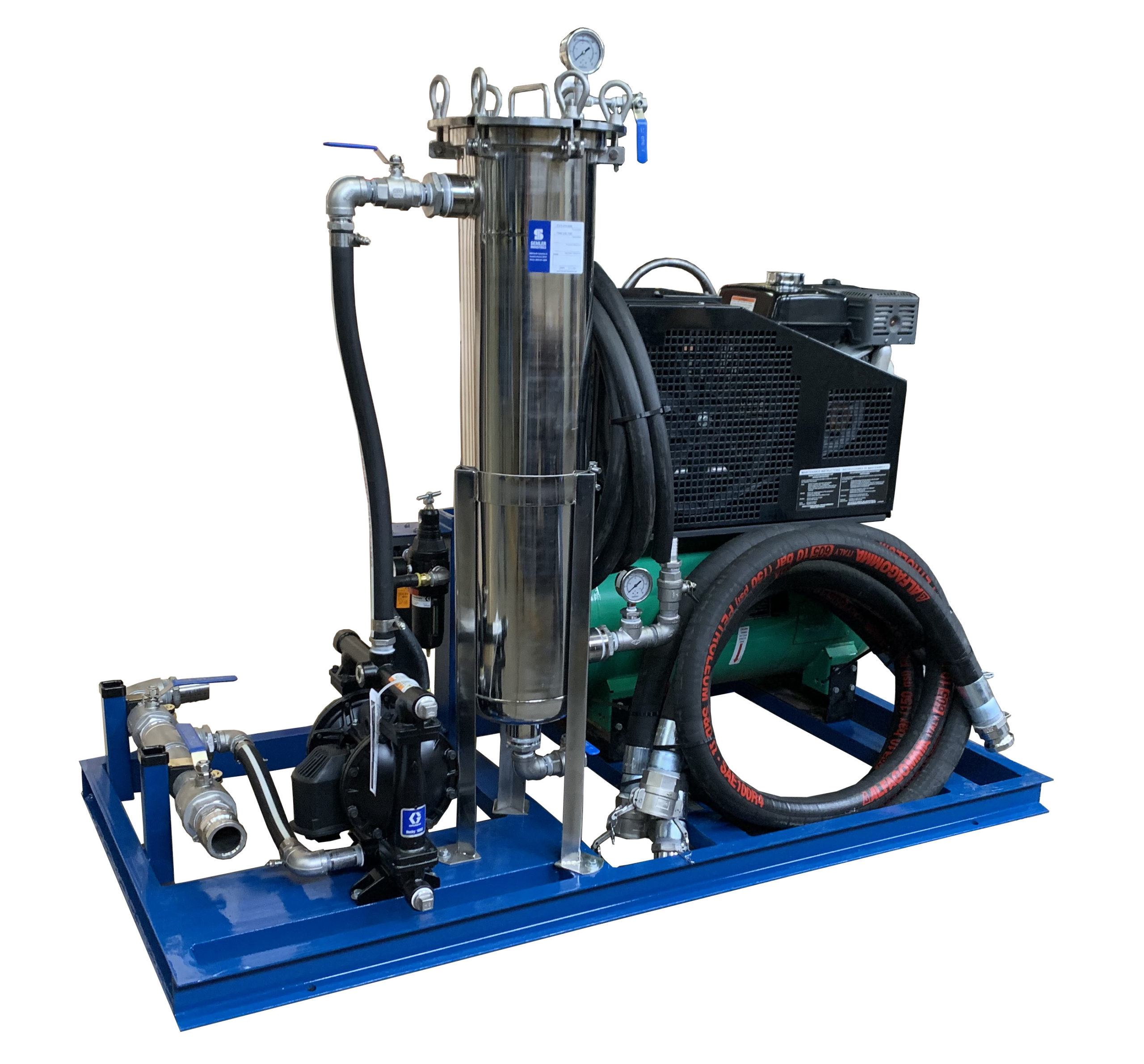

- Designed for high-volume applications such as barge, ship and terminal loading/unloading

- Replaceable liners and end discs allow for rebuilding of the pump without removing it from the piping system

- Excellent self-priming and dry-run capabilities.

Semler Industries also carries a full line of Blackmer Replacement Pump Parts