Automated Blending Skid

Situation

A mix kettle pump station required a transfer system that could handle 100gpm to 120gpm for filling totes and some drum applications. Initially the request was for a pump, but Semler Industries helped to find t overfill costs unnecessary money, proper accuracy and control is essential. Semler had the combined skills for transferring, metering and operating within a reasonable budget.

Case Evaluation

In 2011 the customer contacted Semler industries for help sizing the proper pump for the mix kettle to blend various products such as lube oils, coolants and cleaners. Of course, accuracy is critical for these applications.

After reviewing the application, it was determined that a variable frequency drive (VFD) would be beneficial to control the pump accurately and effectively. This provided additional benefit for the movement of liquids of varying viscosities. In addition, proper metering and measurement would be crucial in controlling the amount of liquid dispensed. System automation allowed the operator to automatically pump, fill drums, totes as well as dribble fill to prevent under/overfill conditions.

Equipment Description

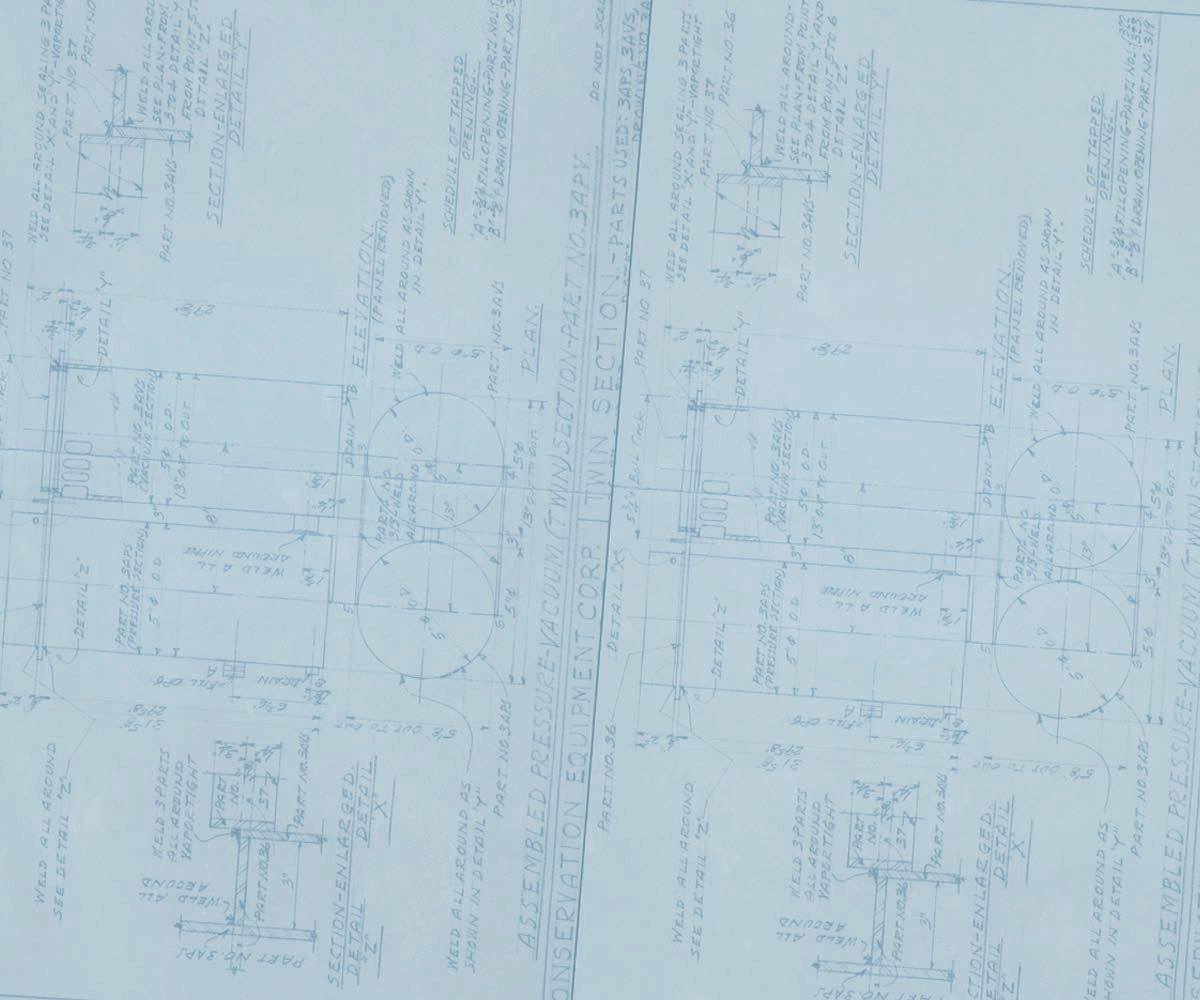

This skid was designed specifically for the blending company, but fell in line with similar blending apparatus that Semler Industries has built for more than 50 years.

A NEMA 4 VFD controler allowed the operator to vary the pump speed for various viscosities as well as “dribble fill” at the end of a primary fill. The equipment included either a Weights-and-Measures approved meter and register with preset or an electronic input for use with a scale. This reduced the overfill of less-controlled processes used prior which included full flow shut-down or manual top off.

Also, due to the spacing in the facility, forklift pockets were included in the skid spacing for portability.

Recommendations

Semler Industries recommends VFD’s for many applications due to the benefit of improved control. Also, meters with a register and preset and input for electronic scales allows for improved accuracy.

References

Joe Palm and Brian Porter; personal files at Semler Industries