Manual Blending

Known for offering the most flexibility, manual blending operations are used to perform small to mid-sized batches and offer high-flexibility and easy adjustments in production. Semler’s equipment and engineering solutions provide more consistency and accuracy while maintaining flexibility for operations.

Automated Blending

Our in-house Engineering resources help take your blending and batching operations to the next level by providing consistency and optimizing material flows. We identify bottlenecks, typically associated with manual tasks, and reduce production time and therefore costs!

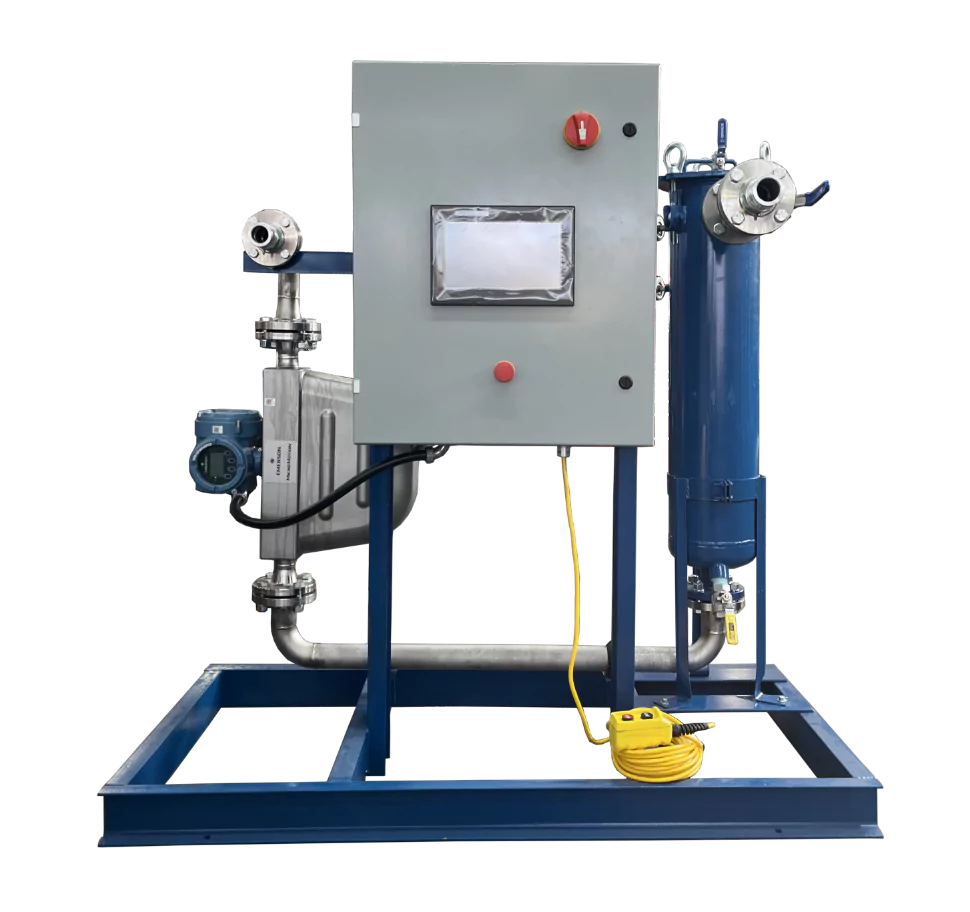

Inline Blending

Semler’s inline blending equipment allows you to make product on-demand without the need for extra holding tanks and mixing equipment. Our team of engineers and equipment experts work to understand your blending processes to determine the best continuous process solution for your production needs. We aim to reduce production time, increase efficiency, and improve product consistency with our customized inline blending solutions!